Brick reinforced mesh and mixed soil have good adhesion and strong tensile strength, which can prevent cement cracking and impact, and make the cement wall more stable.

In addition, it is easy to handle and, when embedded in mortar joints between brickwork or block layers, forms a monolithic structure with high tensile strength, helping to resist stress, vibration and thermal changes.

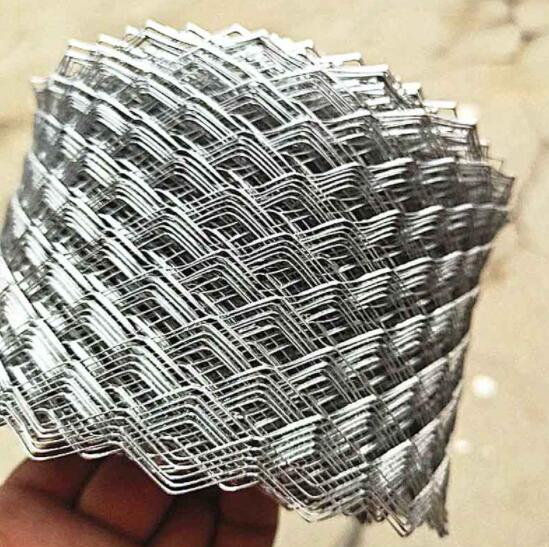

Expanded metal reinforcement has many applications in all types of buildings where additional strength and stability are required, such as in foundations and guardrails, etc., or in areas of local stress. Blends easily into the mortar layer and coils up for easy handling.

PRODUCT DESCRIPTION

Brick wall reinforcement mesh specifications

Material: carbon steel or stainless steel.

Surface treatment: galvanized.

Wire diameter: 2.5-6 mm.

Panel width: 5, 10, 15, 20, 25, 30 cm.

Length of pane: 3 m.

Spacing: 40 cm.

Style: truss mesh reinforcement or trapezoidal mesh reinforcement.

Packing: carton or pallet or plastic packing.

High rigidity, strength and stability.

Welding spots of warp wire and weft wire are on the same surface.

Continuous length of joint reinforcement.

Corrosion and rust resistant.

Durable and long service life.

| Model | SWD*LWD | Coil width | Length |

| BR100 | 15mm*25mm | 100mm | 20m |

| BR150 | 150mm | 20m | |

| BR200 | 200mm | 20m | |

| BR305 | 300mm | 20m |

Block slab structural reinforcement.

Hollow-core slab reinforcement.

Building wall reinforcement.

Support wall reinforcement.

concrete slabbing, roads, paving, foundations, marine work, bank strong rooms, partition slabs, concrete block work, asphalt guttering etc.Installation:

Fix into mortar between brick courses leaving 25mm clearance from face of brickwork. All joints require an overlap of at least 75mm. The mesh can be laid every third brickwork course for most reinforcement.

If you are interested in our products, please contact us.